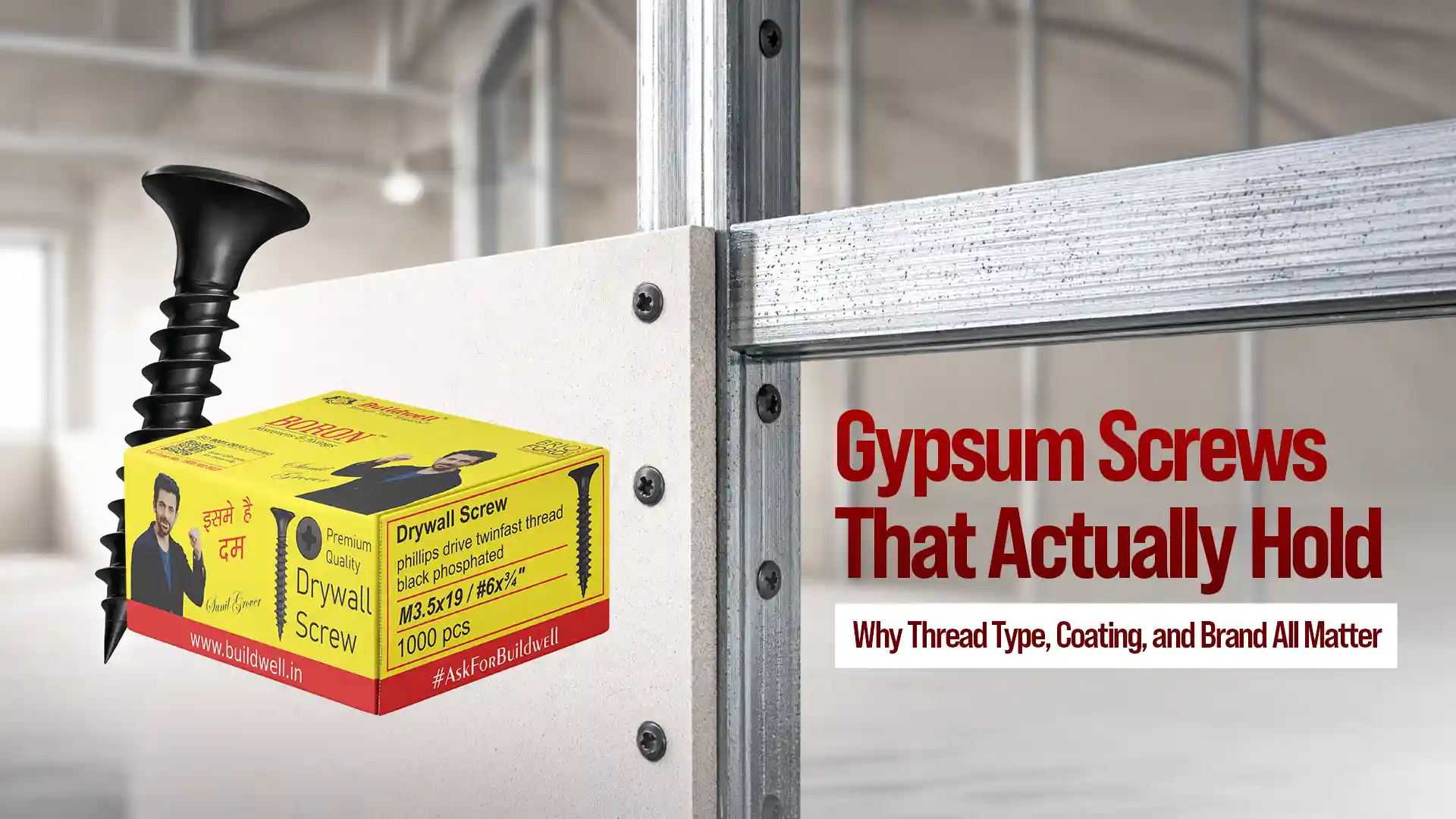

Gypsum Screws That Actually Hold: Why Thread Type, Coating, and Brand All Matter

There’s something oddly humbling about watching a ceiling frame slowly sag because a tiny screw didn’t do its job. No, it wasn’t the plaster. Not the channel. It was the so-called Gypsum Screw that failed under load — sheared, rusted, or slipped.

Ask any experienced contractor, and they’ll tell you: the screw is never “just a screw.” It’s a structural component. It holds panels, keeps grids aligned, and locks in the entire finish. And in Indian site conditions, where humidity, dust, and load are no joke, you can’t afford to compromise.

That’s exactly why Buildwell pays as much attention to fasteners as it does to ceiling boards and plaster systems. If one part fails, the system fails. It’s that simple.

Let’s get into what makes a screw actually reliable — and how Buildwell ensures theirs are built for real jobsites.

Not All Screws Are Made for Gypsum — Start With the Threads

Ever noticed a screw backing out or wobbling when fixed into a ceiling channel?

That’s usually because it’s a generic screw — not a purpose-built Gypsum Screw.

A proper screw for gypsum application must have:

- Sharp self-drilling tip for quick penetration

- Twin threads that grip both board and metal

- Consistent pitch for torque balance

Buildwell screws are designed with high-tensile carbon steel and precision threading — so they grip fast, stay tight, and don’t strip under pressure. That’s what makes the jobsite difference. No “over-turning,” no half-bites, no do-overs.

Coating Is Not Cosmetic — It’s Protection

Here’s a common myth: a black or grey screw just “looks” good. Reality? The coating on your Gypsum Screw determines if it will rust within months — or stay solid for years.

Buildwell uses a phosphate-coated layer that’s corrosion-resistant and site-tested for humid, salty, and dust-prone zones across India. This prevents screw expansion, rust bloom, or bonding loss over time.

Especially in ceiling systems, where screws are invisible but vital, this protection layer is what saves your structure in the long run.

Drive Type Affects Speed and Accuracy

Have you seen site labor struggle with slippage, misfitting screwdrivers, or worn-out heads?

That’s a drive-type issue. Buildwell Gypsum Screw comes with Phillips drive heads for a snug fit with standard bits — speeding up work and reducing material wastage from failed installs.

Faster fastening = faster grid completion = faster plastering. It’s all connected.

Length Matters — and So Does the Application

Too short, and the screw doesn’t anchor properly. Too long, and it risks cracking the board or misaligning the grid.

Buildwell offers a wide range of Gypsum Screw lengths suited for single board fixing, double board systems, or fixing to thick channels. Each pack comes with usage recommendations so even new teams can apply them correctly.

And for big projects? Buildwell sends its site team to guide on the correct screw-grid-board match based on your layout and ceiling plan.

Why Buildwell Treats Screws Like a System Product

Anyone can sell screws. But Buildwell doesn’t stop at product delivery. Their screws are engineered as part of a ceiling system — tested with Buildwell Channels, Buildwell Plaster, and Buildwell Boards.

Because they know that in actual execution, systems work — not scattered parts from different vendors.

Every Gypsum Screw is packed, labeled, and supplied with torque guidelines and application notes. So your team never has to guess.

When Do Most Gypsum Screws Fail?

From Buildwell’s on-site audits, screw failures typically happen due to:

- Using wood screws instead of metal-threaded screws

- No rust protection (especially near bathrooms, kitchens, coastal areas)

- Wrong length for double board applications

- Inconsistent drive tips leading to torque failure

- Cheap materials that shear under vibration or impact

Every time a contractor switches to Buildwell fasteners, these problems go away. Because the screws are designed for ceiling reality — not theory.

Why Buildwell Screws Are Site-Approved

Buildwell doesn’t just ship screws. They educate applicators on correct fastening pressure, placement distance from board edges, and correct angles for ceilings.

They also provide on-site screw tension test support on demand — especially for high-traffic commercial builds where structural integrity is non-negotiable.

This kind of back-end technical support is what makes Buildwell not just a brand — but a site partner.

What You Risk with Cheap Screws

You save a few rupees and get:

- Rattling sounds as the ceiling expands/contracts

- Sagging panels within 6 months

- Visible bulges or plaster cracking at the joint lines

- Increased call-backs and loss of contractor reputation

Buildwell screws are competitively priced, but engineered for performance — not price wars. Because on-site? You either pay now for quality, or pay later in damage control.

A Strong Finish Begins with a Strong Fix

A good ceiling looks flat, seamless, and solid. But none of that happens if your fasteners don’t hold.

Buildwell makes sure its Gypsum Screw range is tested, certified, and compatible with all their other ceiling products. So when you build, you build confidently.

From residential jobs to 100,000 sq.ft commercial sites — the reliability remains the same.

Want Your Ceiling to Stay Silent, Flat, and Problem-Free? Start with Buildwell

📧 Email: sales@buildwell.in

📲 WhatsApp: 7900336699

📞 Toll-Free: 1800 102 8031